Maximising Strength and Efficiency with Markforged's Advanced Fibre Reinforcement TechnologyFibre Reinforcement Redefined: Markforged's Innovative ApproachIn the realm of 3D printing, Markforged stands out for its pioneering work in fibre reinforcement technology. This technology, focusing …

3D Printing South Africa

Camshaft Locking Tool

Punch Torino: A Legacy of Automotive MasteryNestled in Italy's automotive heartland, Punch Torino stands as a beacon of engineering brilliance. Since 2005, Punch Torino had grown from a small spin-off to a leading European R&D facility, employing over 700 experts from 12 nations. Their …

3D Printing – Strengthening the Z Axis Using Co-Part Assembly

Want to gain 87% better strength out of the same part? Check out the latest episode of Markforged Reinforced, where their engineers share valuable tips for designing for additive manufacturing.Introduction: The Power of 3D Printing3D printing is revolutionizing the world of manufacturing. …

[Read more...] about 3D Printing – Strengthening the Z Axis Using Co-Part Assembly

Part Machinist? Cut your machine time in half.

Not familiar with 3D printing? Sure, that's not a problem says Josh Tucker.Josh freely admits that he knew nothing about additive manufacturing before he was shown how to print industrial fixtures that are now essential to the operation of his company.Over the course of more than …

[Read more...] about Part Machinist? Cut your machine time in half.

Strong 3D Printed Fixtures with TITANS of CNC & Markforged

"When it comes to high-end CNC machining, it's all about the fixturing." Titan Gilroy explains how machinists can save money and time by using the additive manufacturing capabilities of Markforged.In this video Titans of CNC Gilroy shows how they use Markforged 3D printers to 3D print fixtures …

[Read more...] about Strong 3D Printed Fixtures with TITANS of CNC & Markforged

Markforged Smooth TPU 95A

When used with Markforged composite printers, Smooth TPU 95A, a rubber-like material, enables product designers and producers to quickly produce flexible, impact-absorbent parts.Markforged Smooth TPU 95A enables manufacturers to produce high-quality, flexible parts on demand. Manufacturers may …

Geomagic Design X 2022 Update

What’s new?New features in this release provide you with new and efficient workflows for reverse engineering complex designs. Improve your modeling speed across common and challenging parts.LiveTransfer to Latest CAD Software VersionsThe following CAD applications are now supported in …

Markforged Video – How to Strengthen Your 3D Printed Parts Along the Z Axis | Reinforced

How we can improve the z-axis strength of our 3d printed parts? This step-by-step video can help you make some of your parts instantly stronger with just a little bit of redesign. Let's look at an example. We're building a part, in this case out of a chopped carbon fibre and nylon material. In this …

YOU MAWO 3D Printed Eyewear

3D printing pioneers for eyewear of the future: personalised made-to-measure frames. Unique & sustainable 3D-printed eyewear, based on a 3D-scan, produced exclusively for the wearer. YOU MAWO benefits from a scalable and reproducible process and a wide range of available colours.Who are YOU …

Markforged X7 Field Edition

The turnkey industrial 3D printer for functional parts in the field. The X7 Field Edition is a ruggedized, field-deployable industrial 3D printer for tactical response to inventory challenges in remote locations.Increase supply chain resilience by printing tools, adapters, and replacement …

Introducing The New DyeMansion Powershot Performance Series

Next level blasting systems purpose-built for the factory of the future & high-volume production with Additive Manufacturing.Talk to us about your post processing requirements …

[Read more...] about Introducing The New DyeMansion Powershot Performance Series

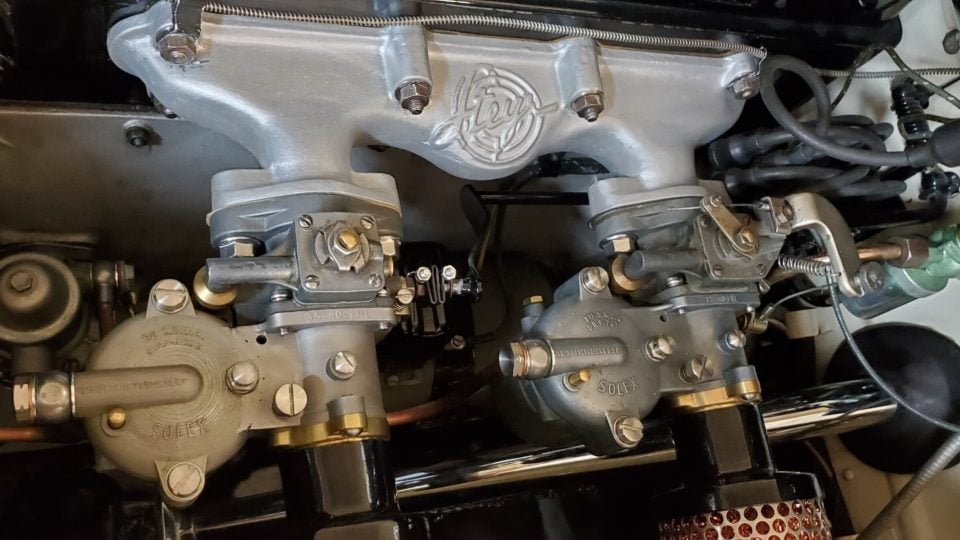

Reverse-engineering automotive parts using metal 3D printing technology

The CustomerRPG Industries is a full-service manufacturer working with automotive, aerospace, and oil industry clients. Started in 1995, the company primarily offers EDM, CNC machining, waterjet cutting, and additive manufacturing services.The ChallengeRobert Ginsburg, President of RPG …

[Read more...] about Reverse-engineering automotive parts using metal 3D printing technology

DyeMansion Announces the Expansion of the Powershot Product Portfolio

On 24 March 2021 , post-processing pioneers, DyeMansion, will introduce the totally new Powershot Performance series and a new generation of their classic Powershot C & S models. The Powershot Performance series is designed for users of industrial Additive Manufacturing targeting serial …

[Read more...] about DyeMansion Announces the Expansion of the Powershot Product Portfolio

Handheld 3D Scanners with AI-Powered HD Mode

Artec 3D announces the successful development of a proprietary AI Engine that more than doubles the resolution of its Eva and Leo handheld 3D scanners to 0.2 mm, using a newly released HD Mode.Artec 3D is the first and only company to utilize deep convolutional neural networks to reconstruct 3D …

[Read more...] about Handheld 3D Scanners with AI-Powered HD Mode

Healthcare shortages resolved using 3D Technology

The 3D printing industry stepped up to the plate when people need them most, assisting to produce tens of thousands of high-quality parts in a matter of weeks. The Covid-19 pandemic found many companies suddenly collaborating with local governments to assist in proving the critical medical …

[Read more...] about Healthcare shortages resolved using 3D Technology