The 3D printing industry stepped up to the plate when people need them most, assisting to produce tens of thousands of high-quality parts in a matter of weeks.

The Covid-19 pandemic found many companies suddenly collaborating with local governments to assist in proving the critical medical devices to fight the shortages in supply the health care industry faced.

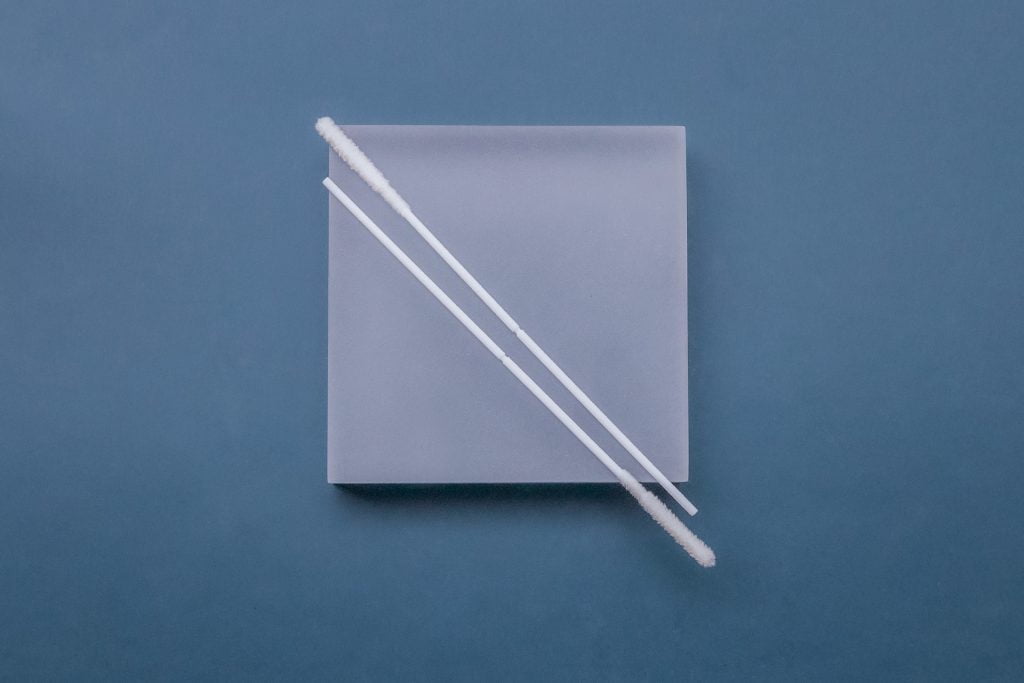

One of the many shortages the industry worked to solve was the production of Nasal swob for Covid-19 test kits. The production of these swobs were not without its challenges; the high demand for for Covid-19 test kits, emphasised that there was minimal nasals swobs being conventionally manufactured. Thats where additive manufacturers stepped in to bridge the gap with their technology.

The first challenge that was that they needed to ensure that the test swob was able to preserve the virus’s integrity to allow RNA detection by means of reverse transcriptase real-time PCR. To do this a solution is needed with a porous-specific activated surface on the head of a highly flexible “stick”.

The second challenge was a cost effective solution to meet the high demand. Aenium and Burloak developed a model for producing up to 40 000 swabs per day on multiple EOS AM systems.

The third challenge was that Nasal swabs are a class IIa medical device. That means a specific certification was required for testing and qualification to fulfill medical standards. Unfortunately, this also required public administration and laboratories to approve the intended use which, typically, is a long certification procedure.

Overcoming the Challenges

Aenium was able to overcome these changes by started clinical trials with the Spanish authorities on April 25, 2020, performing hundreds of clinical comparisons with commercial nasal swabs. The clinical trials, processed the RNA by using onestep RNA teal time PCR using two kits, RT-PCR (BGI) and ref. RR064A (Takara), to detect SARS-CoV-2.

The clinical trail obtained positive results when compared with the same clinical trials over other certified, conventionally manufactured swabs. Aenium and Burloak went on to developed a RNA-free nasal swab with specific laboratory-tested parameters. These nasal swabs were 3D printed on EOSINT P 385, EOS P 396 and EOSINT P 760 systems using EOS PA2200 material.

Clinical performance, technical properties and medical device requirements were all achieved for Europe and North America ensuring the performance of the newly developed swobs. This allowed Rapid Manufacturing Systems to contribute to the mass production of market value nasal swabs.

We have additive manufacturing to thank for a decentralised model that allows Nasal swabs to be produced anywhere in the world. EOS industrial 3D printing polymer solutions are a highly accepted material in the medical sector enabled agile production for a fast response due to supply chain gaps.

The importance of 3D technology has come to light during the Coronavirus outbreak as we saw 3D hobbyists, schools and larger manufacturers printing face masks, face shields, mask adjusters, nasal swabs, hands-free door openers, respirator parts and more.

For more infomation about polymer 3D Printers by EOS reach out to Rapid 3D, your local EOS Polymer Systems partner.