A 3D printed sensor mount on the production line.

In large factories thousands upon thousands of products are made, labeled, checked, and shipped out nonstop.

This factory, owned by Unilever, is responsible for producing hundreds to thousands of bags of Lipton Tea every day. This includes anything from extending machine life to speeding up machine processes, all to save money and improve the machines at the same time.

At factories like this, quick turnaround time is essential to keeping machines running.

“We need to improve our machines in very short amounts of time,” Loska says. “Sometimes there are parts that aren’t working…normally we just model the part, send it to a third party company, and wait for the results.” If a new idea needs to be tested, it can take weeks to get the parts back from a machine shop. This was one of the processes Loska wanted to improve: “It costs us time and money to fix a part. We’ve decided that we wanted to make this process shorter to make some improvements.”

The factory had started with an ABS 3D printer at first, but it hadn’t quite lived up to their expectations:

“We decided that we needed something more, that would produce parts stronger, that we could use during normal production, not just in testing,” Loska explained.

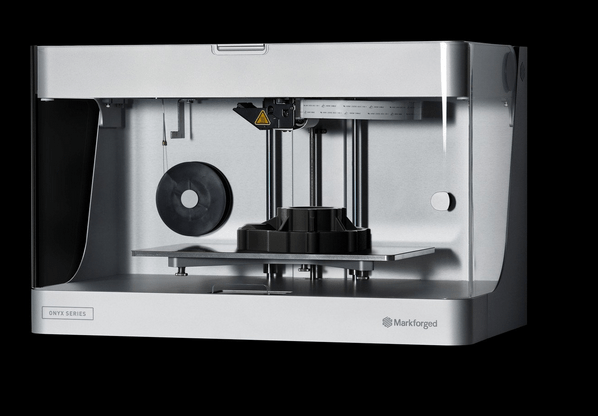

After hearing about Markforged, Loska was convinced: “We decided to test it… we saw that we could make models very quickly with the 3D printer, get stronger parts, not only with fiber materials like fiberglass or carbon fiber, but even with just nylon, we get much stronger parts.”

The prospect of a 3D printer that could create production quality parts was appealing to the entire team:

“We realized this would save a lot of time for us… and everyone who was involved in this kind of work with our machines can see that 3D printing just makes the time shorter for developing new parts or new ideas through to production.” The Markforged printer gave the factory the ability to produce production prototypes at the push of a button.

“These parts are developed very quickly, and it’s about one night to print a few parts for the machine. They are much stronger and more durable than any parts printed on a normal 3D printer.”

Top of the Line.

When Loska and his team find potential areas for process improvements, they can now go straight to their Markforged 3D printer.

“We start looking for any ideas, and during this process all the time we are 3D printing parts.” explained Loska. Once they discover which parts of their manufacturing setup requires improvements, they can use the printer to not only prototype ideas, but to test and load their concepts in a real world environment before finalizing, and printing, the finished product. “In every project, even in safety projects or quality projects, we found it useful to have a 3D printer.” With the capabilities of Markforged, the printer helps develop quality parts in fraction of the time it would take otherwise.

The Eiger view of a sensor mount for sensing rolls of tea bag labels.

From sensor mounts to new production ideas, Loska improved many factory processes using Unilever’s Markforged printer. Instead of waiting for weeks for a part to come in, this process now takes only a single day.

“We make the 3D model in our CAD program, we send it to a 3rd party company…it’s about one week until we get back a good part.” he explains. “When we want to develop this part by ourselves, it takes 24 hours.” The parts the printer has produced can hold up in a factory environment, and that isn’t the only benefit: “Normally it’d be about $50 if we want to send it to another company to make it for us.” Loska said. “The same part costs about $10 on the 3D printer.” Saving cost and time, the part strength Markforged provides has extensively improved production efficiency at the company: “These parts are developed very quickly, and it’s about one night to print a few parts for the machine. They are much stronger and more durable than any parts printed on a normal 3D printer.”